Literature review of suitable test protocols (optionally also ASTs)

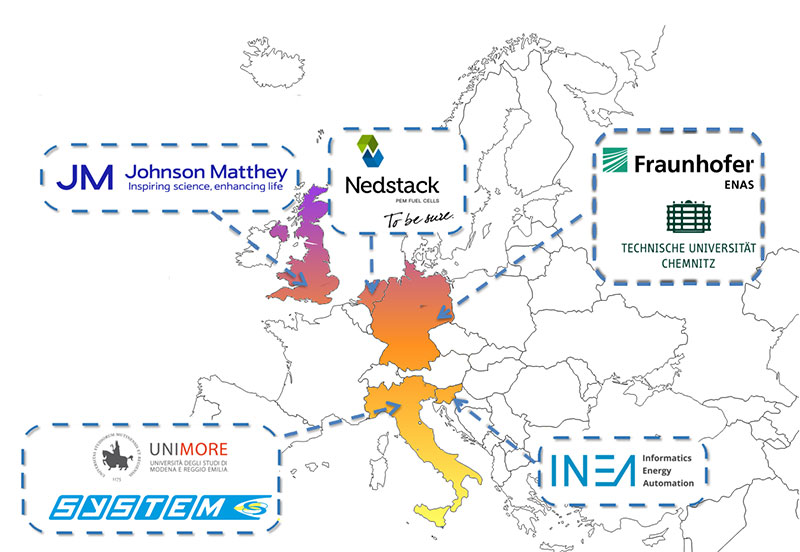

Technische Universität Chemnitz (TUC)

Technische Universität Chemnitz is located in the industrial heart of Saxony, Germany.

TU Chemnitz’s (>2000 employees, >10000 students) profile is based on trans-disciplinarity as well as on national and international networking and it links technical and natural sciences together with social sciences and humanities as well as economics in order to generate competitive and outstanding research.

Department of Advanced Powertrains (ALF)

The Department of Advanced Powertrains (ALF) belongs to the Institute for Automotive Research. ALF, founded in 2010, focuses on automotive technology research and education in the field of electro-mobility. Its staff, with an experience of more than 15 years of working on hydrogen and fuel cells, has a deep insight in fuel cell specifications for automotive applications and is working on innovative layouts for fuel cell systems with optimised components regarding parameters such as efficiency, lifetime and manufacturing costs. Equipped with a chemistry lab with relevant measuring devices and single fuel cell test stands as well as a hydrogen lab for the characterisation of stacks and fuel cell systems, ALF has already carried out research work on different topics, e.g. hydrogen recirculation, scale effects in fuel cell systems and optimisation of operating strategies.

ALF has close connections with car manufacturers and suppliers as well as with Fraunhofer Institute for Manufacturing Processes (IWU) in Chemnitz, working together on reliable and cost-efficient manufacturing technologies for fuel cells in automotive applications. ALF is currently also participating in an FCH JU funded project with an acronym Fit-4-AMandA.

TUC will contribute to the project by the following activities:

Project contact:

The Institute for Print and Media Technology (pmTUC) looks back onto a more than 50-year tradition of education of printing engineers and development of printing tools. Their highly motivated and strongly interdisciplinary staff strives for world-class research and education in the fields of conventional and digital printing methods, large area printed electronics and advanced functionalities, and digital fabrication in sheet-to-sheet and roll-to-roll manufacturing fashion. There are close relationships to the Fraunhofer Institute for Electronic Nanosystems (ENAS) and the Chemnitz Smart Systems Campus, a start-up incubator for SMEs in the field of micro and nanotechnology. The department of DPI is staffed with a wide range of sheetfed and web-fed printing technologies such as screen, gravure and inkjet printers. In addition to the printing equipment, characterisation tools are also available for the investigation of morphological and functional characteristics of the printed layers. The main focus of DPI is to support the transfer of laboratory printing and deposition processes into a close to industry work-flow qualified for industrial manufacturing. In general, DPI will provide technology development, materials deposition by printing technologies such as inkjet printing, screen printing and gravure printing, substrate pre- and post-treatment, layer functionality formation (sintering and curing technologies), and layer morphology and functionality characterisation.

Project contact:

UNIMORE – UNIVERSITÁ DEGLI STUDI DI MODENA E REGGIO EMILIA

UNIMORE was founded in 1175 and is considered one of the best universities in Italy for teaching and research. It is located in two cities situated in the heart of one of Europe’s wealthiest and most dynamic regions according to with Eurostat, which is world-renowned for its production of mechanical parts, engines, sports cars (e.g. Ferrari and Maserati) as well as for its agro-food sector, ceramic tiles and manufacturing industries.

UNIMORE benefits from a longstanding relationship with the area’s firms and corporations, which provide private support for university research and a unique opportunity for on-the-job training before graduation. Statistics show that graduates from the University have excellent job prospects, well above the national average.

Since 2015, UNIMORE is a regular member of N.ERGHY and an interdepartmental laboratory (LIFC) is operative in the study of fuel cells. The Dipartimento di Ingegneria “Enzo Ferrari” (“Enzo Ferrari” Department of Engineering) will be directly involved in the project. It was founded in the academic year 1990-91. The main building, which covers more than 160,000 m², meets the highest teaching and research requirements.

The department regularly cooperates with renowned firms in the car manufacturing, chemical, mechanical, ceramics and biomedical fields, as well as enterprises in the sectors of information technology, telecommunications and industrial electronics. The department has benefited from this productive network, and over the years, it has improved and has further developed the high-quality level of its research and technological application.

Fraunhofer Institute for Electronic Nano Systems

The particular strength of the Fraunhofer Institute for Electronic Nano Systems ENAS lies in the development of smart integrated systems for different applications. Fraunhofer ENAS develops single components, technologies for their manufacturing as well as system concepts and system integration technologies and transfers them into production. The institute offers research and development services from the idea, via design and technology development or realization based on established technologies to tested prototypes.

The Department Printed Functionalities of Fraunhofer ENAS will conduct research and development on how to deposit patterned layers by traditional and digital printing technologies in the MAMA-MEA project. The integration of nanomaterials as well as printed functionalities causes new challenges and requires new approaches in terms of design, testability and reliability.

Johnson Matthey Fuel Cells Ltd.

JMFC is a leading developer, manufacturer and supplier of fuel cell catalysts, membrane electrode assemblies (MEAs), catalyst coated membranes (CCMs) and other components to fuel cell and electrolyser developers worldwide.

JMFC is a partly owned subsidiary of Johnson Matthey plc, a specialty chemicals company and world leader in advanced materials technology with over 13.000 employees in over 30 countries. JMFC develops, manufactures and supplies catalysts, electrodes and MEAs for low temperature proton exchange membrane (PEMFC) and direct methanol fuel cells (DMFC), proton exchange membrane water electrolysers (PEMWE) and high temperature phosphoric acid based fuel cell systems (PAFC) and currently produces several hundreds of thousands of electrode/CCM/MEA product parts per annum.

JMFC has 130 permanent employees, almost all based in the UK. Over 50% of the staff is professional technical personnel with science and engineering qualifications, working in research, product and process development. Significant investments have been made in recent years in world-class fuel cell materials and component research and MEA testing facilities at the parent corporate Technology Centre in Sonning Common, near Reading, and in the world’s first dedicated electrode and MEA manufacturing facility in Swindon, Wiltshire.

Of particular relevance are the multimillion € investments in recent years in advanced production scale coating and converting equipment fully contained in clean rooms with Class 1000 capability. The instrumented coating line has interchangeable coating head capability allowing coating of widths up to 650 mm at speeds up to 30 linear m/minute and has sophisticated dimensional control QC systems.

The converting line enables the high-speed integration of membranes, catalyst layers and edge seals. Senior personnel has considerable experience in participating in, and leading, government supported R&D projects and JMFC has well-established administrative, financial and legal support groups to manage these projects and ensure successful delivery of the contractual requirements.

Current FCH JU projects include DEMCOPEM, VOLUMETRIQ, CRESCENDO, GRASSHOPPER and INSPIRE.

System S.p.A.

The System Group is an international leader in the design and manufacture of production process solutions for the ceramics industry and other industrial sectors such as electronics, intra-logistics and packaging, with a multi-disciplinary approach embracing precision mechanics, electronics, information technology, physics and chemistry.

INEA – Informatics Energy Automation

INEA is leading Slovenian industrial automation, process control and manufacturing informatics company and one of the largest system integrators in this part of Europe.

With over 30 years’ experience in the automation industry, INEA prides itself on its ability and flexibility to deliver the best solutions for your automation requirements, inclusive of the latest technologies and innovations.

Our expertise enables us to offer complete turnkey solutions, to build and/or integrate whole production lines, as well as more specific parts of production lines (like infeed, end of line, etc.), robot cells, and to develop specialised, dedicated machinery to be integrated in-line (like vision inspections systems, rotary tables, etc.), including batching systems for product preparation.

Nedstack Fuel Cell Technology B.V.

Nedstack Fuel Cell Technology B.V (NFCT) manufacturers and commercializes PEM fuel cell stacks. Our customers are system integrators of PEM fuel cells for stationary and transport applications. Together with partners Nedstack also delivers large stationary fuel cell systems, such as the largest PEM power in the world, and have developed and delivered pre-commercial products for road and maritime transport applications.

Nedstack was established in 1999 in Arnhem (The Netherlands) as a spin-off from the PEM fuel cell activities within Akzo Nobel. NFCT has developed PEM power plant know-how in both the Delfzijl PEM 70 kW pilot power plant, the Solvay 1 MW PEM power plant in Lillo, as well as the 2 MW PEM power plant developed and operated under the recent DEMCOPEM project. Nedstack is an active member of the New IG Industry Grouping. In previous FCH-JU funded projects, Nedstack has built up a successful track record of technical development as well as overall project management.